Step onto any Atlanta construction or industrial site—from Midtown high-rises to the Fulton Industrial corridor—and you can feel the organized chaos: moving machinery, dozens of crews, shifting hazards, and tight schedules. Now imagine that same site without clear direction—no marked pedestrian routes, no hazard warnings, no egress guidance. The result isn’t just confusion; it’s risk, delay, and fines.

In high-stakes environments, every minute spent searching for an exit, locating a laydown yard, or hesitating near restricted zones increases risk and costs. Poor wayfinding creates operational drag; missing or non-compliant warnings create regulatory exposure. Strategic, durable, OSHA/ANSI-aligned signage fixes both—turning chaotic spaces into safer, faster, and more compliant Atlanta job sites.

Wayfinding signs and safety signs are often viewed as simple overhead costs, but this perspective is fundamentally flawed. They are, in reality, non-negotiable, high-efficiency safety infrastructure that pay for themselves through risk mitigation. Compliance is mandatory, but strategy is optional.

Businesses that treat signage as a minimal requirement often find their generic, faded materials failing when they are needed most. This post will detail how strategic, durable signage ensures OSHA compliance, minimizes accidents, and dramatically improves the entire operational flow, transforming a confusing job site into a safe, efficient, and profitable one.

To truly protect your project and your people, you must understand the two critical, high-cost areas where poor signage creates maximum liability: regulatory risk and operational drag.

The Regulatory Imperative: OSHA and ANSI Compliance

For any construction or industrial operation, safety signage is a legal mandate enforced by federal regulatory bodies. If a serious injury occurs, one of the first things investigators examine is the state and compliance of your posted warnings.

The Safety and Health Administration (OSHA) requires employers to communicate workplace hazards effectively to all employees. Clear, visible OSHA signs are the primary medium for this communication. Studies show that Failure to communicate hazards is one of the most frequently cited OSHA violations. Investing in proper signage is therefore a proactive measure against one of the most common and costly infractions faced by the industry.

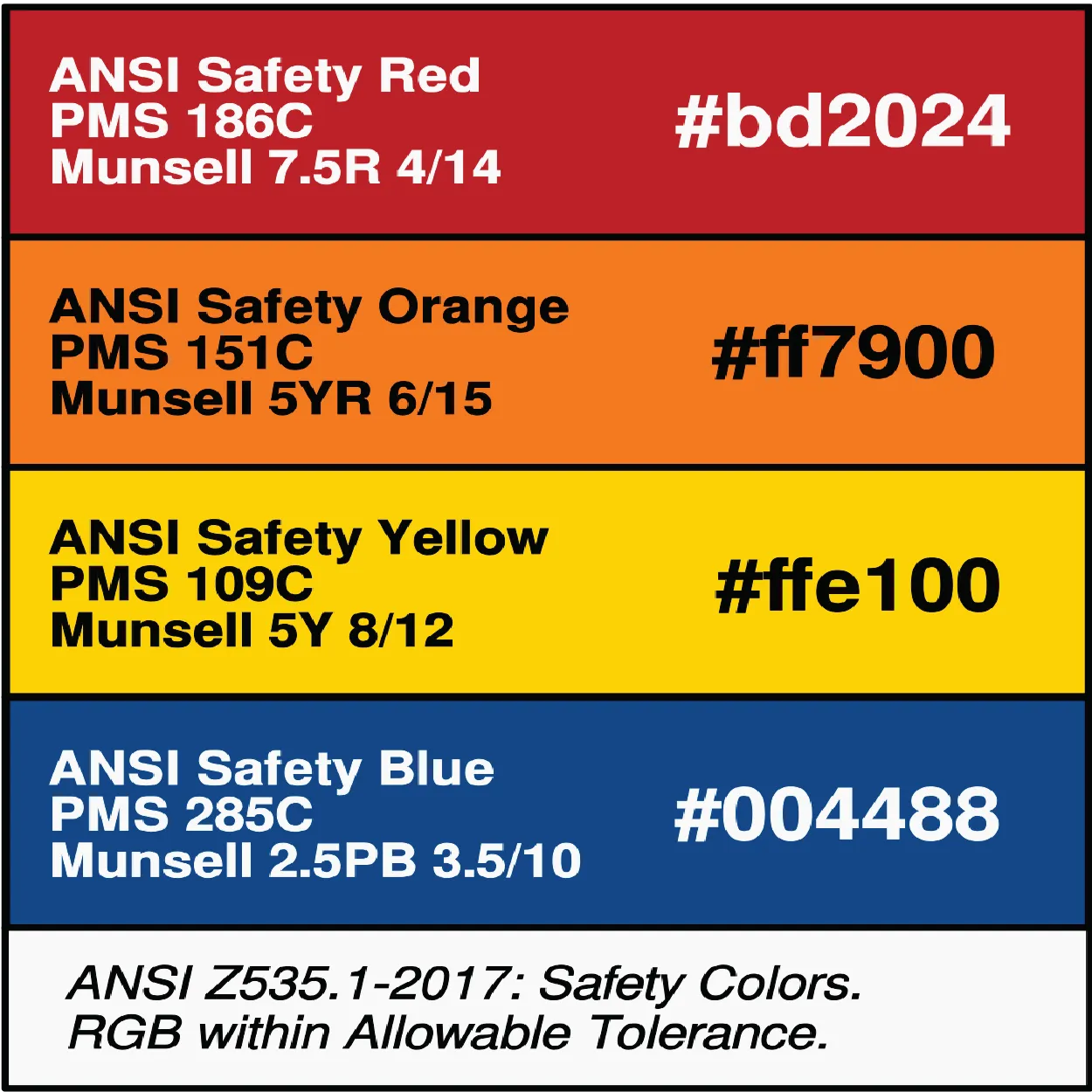

While OSHA sets the federal requirement for safety, the American National Standards Institute (ANSI) Z535 Standard sets the standard for how safety signs must look. The ANSI Z535 series provides the universally recognized framework for design, color, size, and application, ensuring every worker, regardless of language or site, can interpret the sign instantly. The uniformity dictated by ANSI Z535 is crucial because it reduces recognition time. When a sign is standardized, workers are trained once and that recognition carries over to every site, significantly decreasing risk exposure.

Safety First: The Hierarchy of Hazard Signage

Adherence to ANSI's visual language is paramount, as deviation can confuse workers and lead to serious consequences. The difference between headers is a difference of legal severity and potential outcome:

-

DANGER (Red): The most severe hazards—those that will result in death or serious injury if not avoided (e.g., high-voltage electricity, toxic storage). The red header commands immediate, often reflexive, cessation of activity.

-

WARNING (Orange): Indicates a serious hazard that could result in death or serious injury (e.g., moving machinery parts, areas with falling objects). The message dictates careful action and vigilance.

-

CAUTION (Yellow): Addresses less severe risks that could result in minor to moderate injury (e.g., wet floors, low overhead clearance, required moderate PPE). This color flags general awareness.

-

NOTICE (Blue): Used for instructions, rules, and general information not directly related to injury prevention (e.g., security policies, visitor parking, operational procedures).

-

General Safety (Green): Indicates the location of safety equipment or safety-related instructions (e.g., first aid stations, emergency exits).

A compliant sign is also required to contain a relevant pictogram and a message panel that provides concise text instructions. Furthermore, for chemical hazards, modern signs must integrate the Globally Harmonized System (GHS) pictograms, linking directly to OSHA's mandate for clear chemical communication. Custom printing is essential for integrating these complex, layered standards onto a single, legible asset.

Legal Liability and Due Diligence

Faded, broken, or non-compliant signage exposes your company to significant legal risk. Proper signage demonstrates “due diligence,” proving to regulators, insurers, and courts that every reasonable step was taken to warn workers of known risks. This diligence is especially important in preventing costly worker compensation claims. An illegible or missing sign is a direct failure to warn, which can be devastating in a liability case. Conversely, using non-standard or homemade signs can invalidate your due diligence claim, potentially escalating negligence claims in the event of an accident. Compliance protects both the worker and the business's bottom line.

Efficiency and Flow: The Wayfinding Strategy

While safety signage prevents accidents, wayfinding signage prevents wasted time, frustration, and logistical errors. In the fast-paced, high-stakes world of construction, efficiency is safety, and organization is profitability.

A well-designed wayfinding signs system ensures that every person on site—from first-day laborers to delivery drivers and site inspectors—can quickly find their destination without disrupting workflow or wandering into restricted areas. This clarity saves money: if 100 workers spend just two minutes a day searching due to poor signage, that equates to over three lost hours of productivity daily.

Traffic Management and Collision Reduction

Heavy equipment, forklifts, delivery trucks, and pedestrian traffic all share space on a job site, making collision avoidance a constant priority. Clear wayfinding for traffic management is essential, covering:

-

Ingress/Egress Protocols: Clearly marking entrance, exit, and staging areas for large delivery vehicles to prevent bottlenecks.

-

Designated Paths: Separating pedestrian walkways from machinery routes using barriers and highly visible floor graphics.

-

Internal Routing: Providing clear direction to loading docks, laydown yards, and material storage points, reducing costly time spent hunting for materials.

Studies have indicated that Poor site logistics management can add 10-15% to project schedules. Wayfinding is a core component of logistics management, and investing in high-visibility directional signage is a preventative measure against costly delays caused by traffic obstruction or accidents.

Emergency Egress and Response

In an emergency, seconds count. Wayfinding is critical for life safety. Clear directional arrows pointing to exits, assembly point signs, and visible markers showing the location of critical response equipment can mean the difference between a near-miss and a fatality. A comprehensive, audited wayfinding system ensures responders, too, can quickly navigate the site to the point of origin.

The Material Mandate: Durability, Visibility, and Longevity

The single greatest difference between compliance failure and success is investing in material durability. The solution is moving beyond generic print to strategic signage engineered specifically for the job site environment.

Generic signs degrade quickly under the relentless assault of environmental factors: UV fading, chemical splashes, moisture, and abrasion. We eliminate this failure point by utilizing specialized printing techniques and industrial-grade materials. When assessing the cost of signage, consider the Life Cycle Cost (LCC)—a low-cost paper sign that fails in three months costs far more over a multi-year project than a premium, durable sign that lasts the entire duration.

Optimal Materials for Industrial Graphics

Choosing the correct substrate is paramount for sign longevity and function:

-

Aluminum: Ideal for permanent, rigid regulatory and traffic signs that require years of structural integrity. Its rust-proof nature makes it superior for outdoor use.

-

High-Tack Vinyl and Floor Graphics: Essential for adhering warnings and information to equipment, uneven walls, concrete pillars, and for defining pedestrian paths on the ground. Specialized vinyl offers chemical resistance against oil and solvents.

-

Reflective and Photoluminescent Materials: Reflective signs ensure visibility when illuminated by headlights or flashlights at night. Photoluminescent (Glow-in-the-Dark) materials are critical for emergency egress signs, ensuring paths are visible even during total power outages.

Printing Techniques for Superior Performance

The print method itself determines a sign’s lifespan. We utilize specialized processes to ensure maximum durability:

-

UV-Cured Inks: These inks are instantly hardened by ultraviolet light, making them exceptionally resistant to fading, scratching, and chemical breakdown. This is the first line of defense against the harsh sun.

-

Durable Lamination: Applying a heavy-duty, clear laminate coating creates a protective shield against physical abrasion and cleaning chemicals, ensuring the sign remains legible through severe conditions.

-

Specialized Coatings: For sites prone to vandalism, anti-graffiti coatings can be applied, allowing for easy cleanup without damaging the graphic beneath. Anti-glare finishes ensure maximum readability even in direct, intense sunlight.

We emphasize the durability of our industrial graphics because we know a compliant sign is only effective if it remains readable and intact.

Best Practices: Placement and Audit

The most crucial step after production is deployment. A high-quality sign placed incorrectly is as useless as a faded one.

The Science of Visibility

Sign placement must adhere to the principle of immediate recognition. Visual aids with high contrast and minimal clutter significantly reduce processing time, leading to faster recognition and reaction. Factors that dictate visibility include:

-

Viewing Distance: Sign size must be proportional to the distance from which it must be read (e.g., text height needs to be 1 inch for every 50 feet of viewing distance).

-

Illumination: Critical signs must meet specific lux levels and utilize reflective or photoluminescent materials to maintain 24-hour visibility.

-

Sign Placement: Signs should be mounted at eye level or above to avoid obstruction by machinery or materials, and away from visual clutter that could compete for attention.

The Tools for Continuous Compliance

Signage is not a set-it-and-forget-it asset. Construction sites are dynamic, meaning hazards shift, signage gets damaged, and new requirements emerge weekly. Site management must stress the need for a regular site audit to verify that every sign is present, legible, and relevant. We specialize in producing the durable, compliant signage that these audits require, ensuring your site managers have the reliable physical assets needed for ongoing maintenance.

Customization for Universal Safety

Template signs are a start. Custom OSHA/ANSI designs tailored to equipment, workflows, and multilingual crews reduce ambiguity and support training carryover between Atlanta sites (Midtown, Buckhead, West Midtown, Decatur, Marietta, Alpharetta, Smyrna, Roswell).

Where We Work in Metro Atlanta

We design, print, and (optionally) install construction wayfinding and safety signage across Atlanta, GA and nearby areas, including Downtown, Midtown, Buckhead, West Midtown, Fulton Industrial, Sandy Springs, Decatur, Marietta, Smyrna, Alpharetta, Roswell, and more.

Signage as an Investment

The argument for strategic, custom, and durable signage boils down to one simple truth: it is an investment, not an expense. The cost of a few custom signs is negligible compared to the cost of a single OSHA violation, a lost-time injury, or a critical project delay.

Wayfinding and safety signs fundamentally improve the working environment by creating clarity, reducing stress, and enforcing safe behavior. This commitment to worker protection, efficiency, and compliance yields measurable returns in reduced liability, fewer accidents, faster project completion, and improved worker morale.

Don't let your safety strategy rely on generic, faded, or non-compliant paper thin signs. Choose durable, custom print solutions designed to last as long as your job requires and ensure everyone goes home safely.

Get an Atlanta Job Site Signage Quote

Need to improve job site safety and efficiency? We design, print, and install durable, OSHA/ANSI-ready signage for Atlanta projects—with fast turnaround.

Rush printing/installation available across Metro Atlanta. Get a quote today.